Capabilities

Leading EMS provider in the Indian mobile phone industry

Tap into our expertise in complex machining and experience superior mechanical, technical, final assembly and SMT capabilities to develop landmark products for your portfolio. Quality is our second name and that makes us a perfect partner for all your integration requirements from prototyping to manufacturing to quality testing across the value chain.

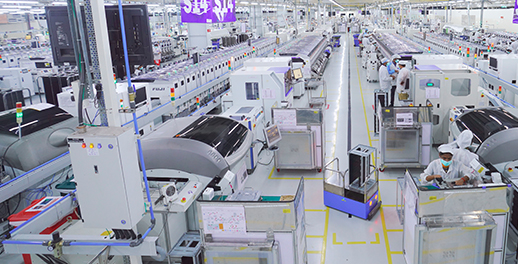

VERTICALLY INTEGRATED PRODUCTION

LARGEST CAPACITY IN THE REGION

360° INTEGRATION OF PRODUCT LINE

With power, comes responsibility. Being the economic driving force in the region, we are constantly challenging ourselves to enhance our product capabilities and set higher standards with process and quality. To augment the value chain, we are constantly ramping up our production architecture from L1 to L10 capabilities. These operations are supported by developing an ecosystem of world class local suppliers to support the value chain.

Our Expertise

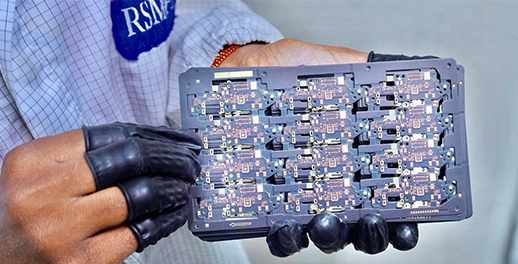

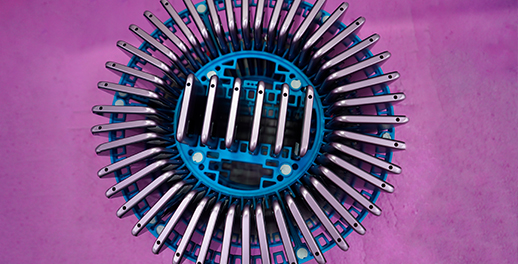

We manufacture and assemble our products on build-to-order or configure-to-order basis. As customers seek to provide greater functionality in physically smaller products, they increasingly require more sophisticated manufacturing technologies and processes. Our investment in advanced manufacturing equipment and our expertise in innovative miniaturization, packaging and interconnect technologies, enables us to offer a variety of leading-edge manufacturing solutions.

Unique manufacturing solutions that are aimed to create maximum convenience for our customers.

• Automated Continuous Flow - We are pioneers in Automated in-line assembly process where various pieces of equipment are joined directly or on conveyor belt. This automation supersedes batch production and enhances production efficiencies leading to faster and more quality-controlled manufacturing.

• Computerised Control and Monitoring - We support all aspects of our manufacturing activities with advanced computerised control and monitoring systems. Materials planning, purchasing, stockroom and shop floor control systems are supported through a computerised manufacturing resource planning system. We have enabled our customers to remote-access our systems to monitor real-time yields, inventory positions, work-in-process status and vendor quality data of their products.

• Electronic Supply Chain Management – On-time delivery is our motto. With electronic supply chain management, our customers can share product demand and forecasts through electronic data interchange using web-based tools.

We offer systems assembly, test, direct-order fulfilment and configure-to-order services to our customers. Our systems assembly services extend our range of assembly activities to include assembly of higher-level sub-systems and systems incorporating multiple PCBAs. We also offer direct-order fulfilment and configure-to-order services for delivery of final products.

Our expertise in precision tooling and moulding enables us to manufacture in-house many of the components that we use in our production processes. We have developed expertise in customising components for use in manufacturing products for our customers thus reducing our unit costs of production and give an innovative edge to the product and leverage more secure business.

Our aim is to create leading-edge products that will change the world and give a competitive edge to our customers. With the launch of our state-of-art R&D centre in IIT Madras Research Centre, we are one step closer to providing customized solutions to our customers that will revolutionize the markets. Our research is also boosted with the experience of the global team that provides constant tech support.